High-precision molds are necessary for the manufacturing many products as they allow for uniformity and quality, even in mass production. But when dozens of tons of large molds are required for the production, every step of mold operation can be much more difficult.

Take the production of bumper molds for example, the mold size is typically up to several meters. So if traditional bridge cranes are used for mold lifting, spotting and reversing, the personal safety of operators cannot be guaranteed and the production efficiency can be extremely low.

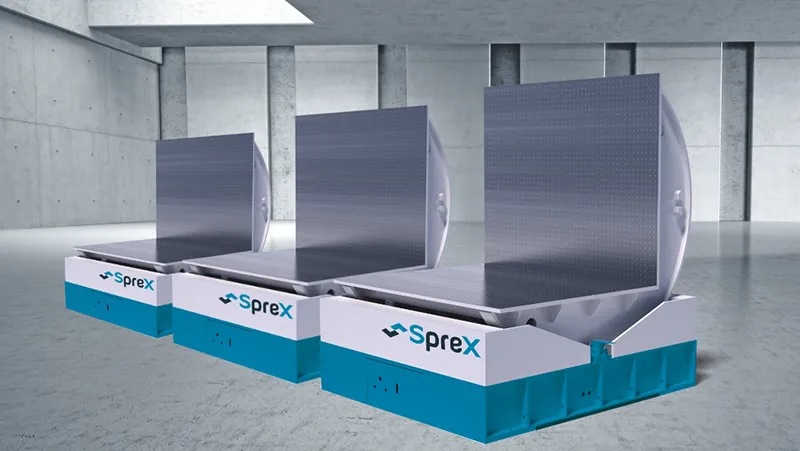

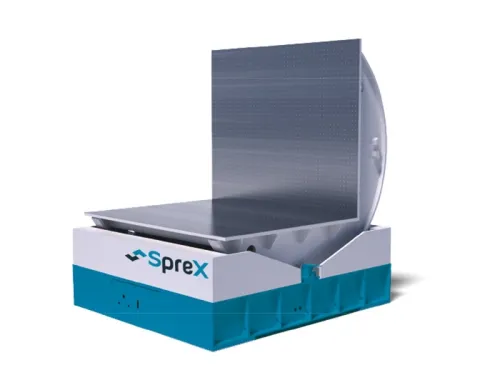

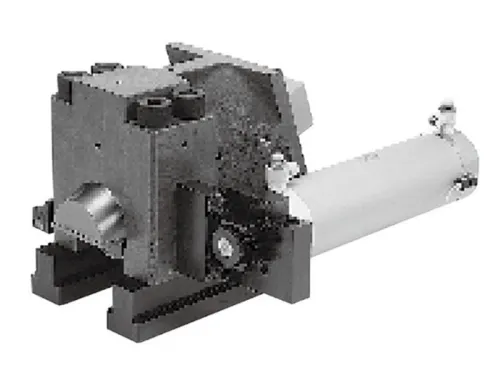

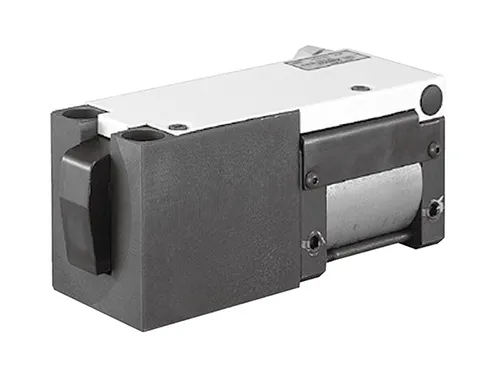

The products of Shunxing are designed specifically for these problems. We developed our die spotting press, mold reversing machine, and quick mold change system three series of products to fix the mold in order to allow it to be moved more securely, increasing the spotting precision. Shunxing products ensure high efficiency in both the manufacturing process and operation.