Technical parameter

FW2-S

- Clamping force (25MP): 20 kn

- Max. clamping stroke: 150 mm

- Driving air pressure: 0.4-0.55 mp

- Clamp moving speed: 30-80 mm/s (adjustable)

FW4-S

- Clamping force (25MP): 40 kn

- Max. clamping stroke: 150 mm

- Driving air pressure: 0.4-0.55 mp

- Clamp moving speed: 30-80 mm/s (adjustable)

FW6-S

- Clamping force (25MP): 60 kn

- Max. clamping stroke: 200 mm

- Driving air pressure: 0.4-0.55 mp

- Clamp moving speed: 30-80 mm/s (adjustable)

FW10-S

- Clamping force (25MP): 100 kn

- Max. clamping stroke: 300 mm

- Driving air pressure: 0.4-0.55 mp

- Clamp moving speed: 30-80 mm/s (adjustable)

FW25-S

- Clamping force (25MP): 250 kn

- Max. clamping stroke: 300 mm

- Driving air pressure: 0.4-0.55 mp

- Clamp moving speed: 30-80 mm/s (adjustable)

FW50-S

- Clamping force (25MP): 500 kn

- Max. clamping stroke: 300 mm

- Driving air pressure: 0.4-0.55 mp

- Clamp moving speed: 30-80 mm/s (adjustable)

Optional type

| Type | Clamping force(25MP) | Mix clamping stroke | Driving air pressure | Clamp moving speed | Weight |

| KN | mm | MP | mm/s | kg |

| FW2-S | 20 | 150 | 4 | 30-80 Adjustable | 2 |

| FW4-S | 40 | 150 | 4 | 4.8 |

| FW6-S | 60 | 200 | 4 | 7.2 |

| FW10-S | 100 | 300 | 5 | 13 |

| FW16-S | 160 | 300 | 5 | 23 |

| FW25-S | 250 | 300 | 5 | 36 |

| FW50-S | 500 | 300 | 5 | 80 |

Type selection

You can select the corresponding clamp type and number according to your equipment needs.

| Machine Capacity | Specs of the hydraulic clamping system | Thickness of mold platen(mm) |

| Fixed platen | Number | Movable platen | Number |

| 650-850 | FW16-S | 4 | FW16-S | 4 | 50 |

| 900-1300 | FW16-S | 6 | FW16-S | 6 | 50 |

| 1400-1600 | FW25-S | 6 | FW25-S | 6 | 50 |

| 1800-2800 | FW25-S | 8 | FW25-S | 8 | 60 |

| 3300-4000 | FW50-S | 8 | FW50-S | 8 | 60 |

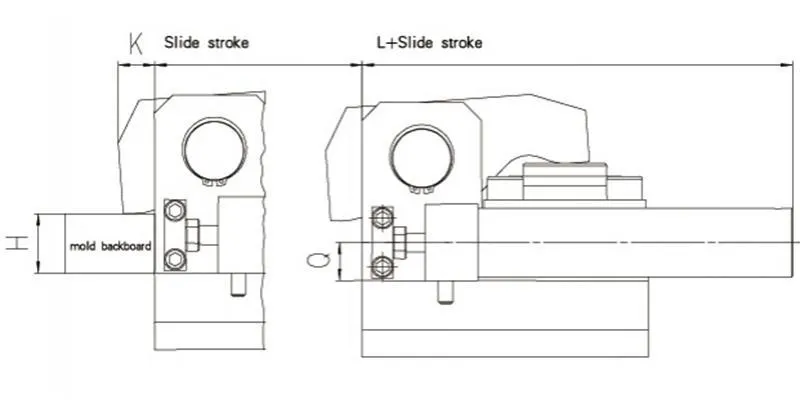

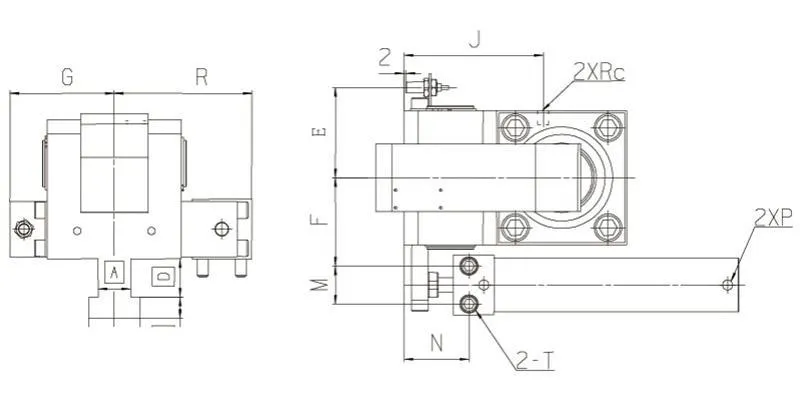

Dimensions

| Specification | G | R | J | E | F | M | N | Rc | T | P | Q | K | L | H(Standard) |

| FW2 | 60 | 65 | 58 | 46.5 | 39.5 | 18 | 1/4 | 48 | M5X35 | 1/8 | 15 | 18 | 108.5 | 25 |

| FW4 | 66 | 72 | 80 | 54 | 47 | 18 | 1/4 | 70 | M5X35 | 1/8 | 15 | 23 | 108.5 | 30 |

| FW6 | 80 | 92 | 85 | 66 | 58 | 24 | 1/4 | 76 | M8X45 | 1/8 | 21 | 30 | 119 | 30 |

| FW10 | 90 | 110 | 109 | 75 | 66 | 32 | 1/4 | 95 | M10X55 | 1/8 | 26 | 30 | 137 | 40 |

| FW16 | 100 | 119 | 125 | 84 | 75 | 32 | 1/4 | 120 | M10X55 | 1/8 | 26 | 30 | 137 | 50 |

| FW25 | 113 | 150 | 150 | 97.5 | 95.5 | 41 | 1/4 | 135 | M12X70 | 1/4 | 32 | 30 | 163 | 50 |

| FW50 | 155 | 200 | 200 | 140 | 135 | 110 | 1/4 | 160 | M16X85 | 1/4 | 38 | 30 | 172 | 60 |

Note: H is the thickness of mold base plates that are paired with standard hydraulic clamps. Customization is available upon request.

Features

- Advanced electrical system controller featuring an OMRON programmable controller, ensuring precise control and user-friendly operation interface.

- Multiple layers of safety protection, ensuring the safety of operators and preventing any potential hazards during the clamping process.

Related Products