Technical parameter

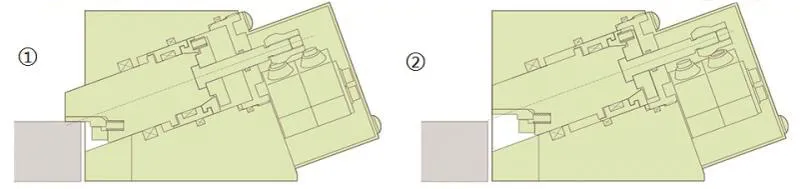

Optional type

| Type | Die clamp capacity | Clamping force (Normal 13.7MPa)(kN) | Retention force(Oil pressure OMPa) (kN) | Clamp reserve | Oil cylinder volume(cm3) | Operating temperature | Operating frequency |

| (kN) | (mm) | Clamping | releasing |

GWA0100 | 9.8 | 9.8 | 3.9 | 1.0 | 6 | 3 | 0~70℃ | Below 20 times/day (or you need contact us) |

GWA0160 | 15.7 | 15.7 | 6.3 | 11 | 4 |

GWA0250 | 24.5 | 24.5 | 9.8 | 19 | 8 |

GWA0400 | 39.2 | 39.2 | 15.7 | 35 | 13 |

GWA0630 | 61.7 | 61.7 | 24.7 | 64 | 24 |

GWA1000 | 98 | 98 | 39.2 | 1.5 | 121 | 48 |

GWA1600 | 157 | 157 | 62.8 | 227 | 102 |

GWA2500 | 245 | 245 | 98.0 | 411 | 177 |

GWA4000 | 392 | 392 | 156.8 | 757 | 349 |

GWA5000 | 490 | 490 | 156.8 | 757 | 349 |

Note: The mold clamping part thickness precision should be less than ±0.5mm.

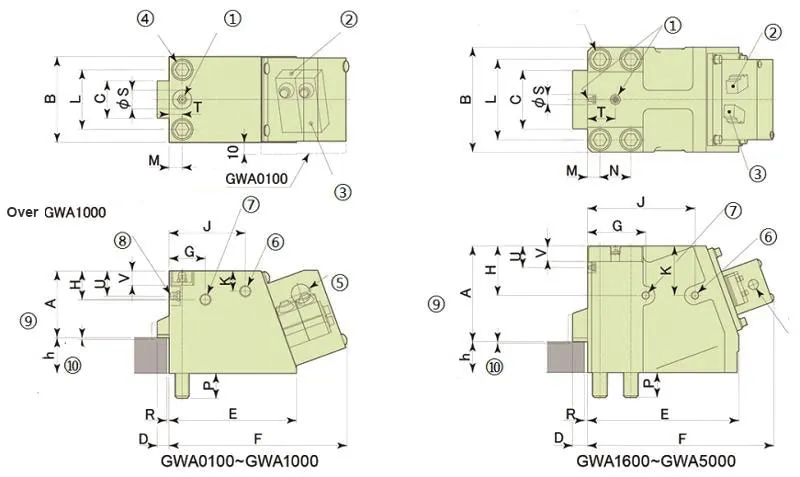

Detailed machinery

Dimensions

| Type | A | B | C | D | E | F | G | H | J | K | L | M | N | P | Q | R | S | T | U | V | Rc | (Standard)h±0.5 |

| GWA0100 | 41 | 48 | 20 | 8 | 81 | 129 | 21.5 | 19.5 | 48.5 | 8 | 33 | 8 | - | 12 | M8 | 1.5 | 16 | 10 | - | 8 | 1/8 | 20 |

| GWA0160 | 48 | 58 | 25 | 9 | 93 | 140 | 28 | 23 | 56.5 | 9.5 | 39 | 9.5 | - | 17 | M10 | 12 | 10 |

| GWA0250 | 56 | 72 | 31.5 | 10 | 107 | 150 | 30.5 | 24 | 64 | 17 | 50 | 11 | - | 21 | M12 | 2 | 11 | 12 | 30 |

| GWA0400 | 69 | 90 | 40 | 12 | 123 | 173 | 38 | 30 | 70.5 | 14 | 62 | 14 | - | 27 | M16 | 14 | 16 | 1/4 |

| GWA0630 | 82 | 110 | 50 | 14 | 140 | 194 | 41 | 33 | 83 | 22 | 76 | 17 | - | 33 | M20 | 3 | 15 | 20 | 35 |

| GWA1000 | 98 | 135 | 63 | 17 | 152 | 208 | 44 | 50 | 102 | 50 | 95 | 20 | - | 36 | M24 | 20 | 24 | 40 |

| GWA1600 | 128 | 138 | 75 | 20 | 205 | 256 | 80 | 63 | 143.5 | 63 | 104 | 17 | 40 | 33 | M20 | 5 | 40 | 35 | 21 |

| GWA2500 | 155 | 170 | 95 | 24 | 245 | 302 | 94 | 80 | 174 | 80 | 130 | 20 | 50 | 40 | M24 | 45 | 25 | 50 |

| GWA4000 | 195 | 215 | 118 | 28 | 305 | 355 | 119 | 90 | 208 | 90 | 162 | 27 | 60 | 50 | M30 | 65 | 40 | 35 | 3/8 |

| GWA5000 | 195 | 215 | 118 | 28 | 305 | 355 | 119 | 90 | 208 | 90 | 162 | 27 | 60 | 50 | M33 | 65 | 35 |

Related Products