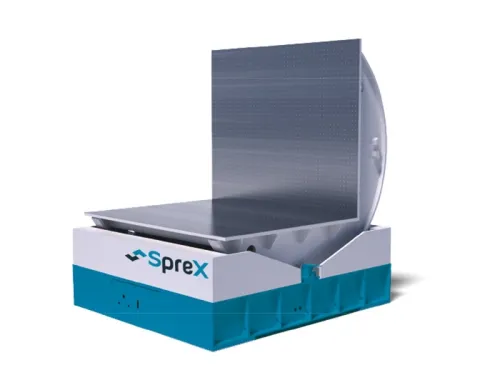

Hydraulic Die Spotting Press (Impact Simulation Type), ST Series

This advanced hydraulic die spotting press utilizes the tremendous impact force generated during the moment of contact in freefall, replacing the conventional static pressure used in die presses for inspection purposes, resulting in superior die spotting quality compared to traditional die spotting presses of the same mold surface size.

The hydraulic die spotting press is engineered with meticulous attention to detail. High standards of configuration and computer-aided design ensure exceptional performance. Critical components are processed using state-of-the-art machining centers to guarantee precision, while advanced heat treatment techniques enhance the durability of important and wear-prone parts. The hydraulic system combines high-performance hydraulic components in an optimized configuration, while the control section features a dedicated die spotting press computer control system.